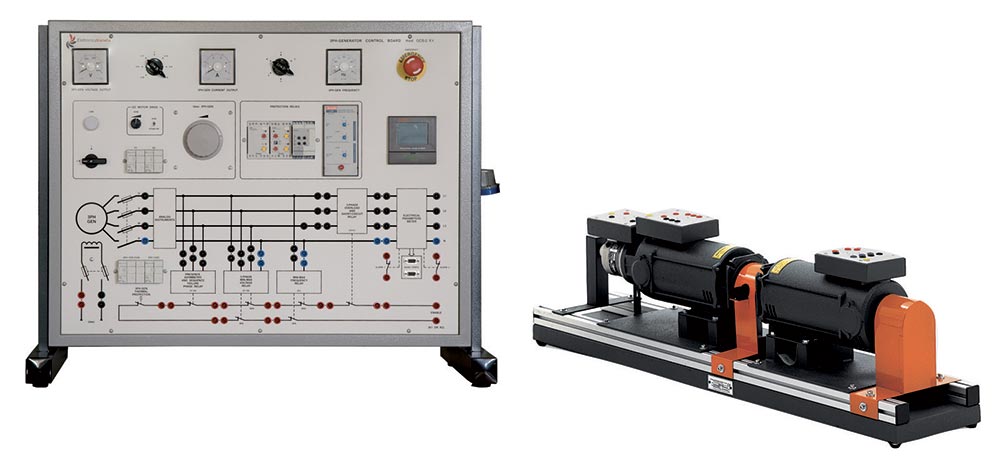

EV SYNCHRONOUS MOTOR-GENERATOR SET Mod. MGS-1/EV

Features

SKU: Machines

Category: Electrical Training Equipment, Power Generation, Distribution & Consumption

TECHNICAL CHARACTERISTICS:

The set consists of a base and of the electric rotary machines, it may be positioned an any working top or close to the control module. The base is made of chemically treated sheet steel, painted with many epoxy coats; the base is provided with rubber feet and it enables to couple the machines in a very quick way.

It is also provided with safety covers to be put over the couplings so that moving parts become inaccessible, and it includes an accessory to lock the shaft of the machine for tests with locked rotor (short circuit).

The electric rotary machines have structural shape B3 and a protection degree IP 22.

- Direct current motor:

- Rated power = 1100 W

- Armature voltage = 160 Vdc

- Speed of rotation = 3000 rpm

- Separate excitation

- Tachogenerator of 0.06 Vdc/rev, coupled to the motor

- Thermal protector integrated in the windings

- Three-phase synchronous salient pole alternator:

- Rated power = 1000 VA

- Armature voltage = 3 x 230/400 Vac

- Star delta connection

- Speed of rotation = 3000 rpm

- Separate excitation = 220 Vdc

- Thermal protector integrated in the windings

- Power supply: It is powered by control and protection

- module mod. GBC-2/EV

- Dimensions: 1200 x 260 x 300 mm

- Net weight: 65 kg

TRAINING PROGRAM:

Training refers to the study of machines for power generation and to control and regulation devices. The range of application of these devices is related to both big high-voltage power plants and small autonomous and/or low-voltage co-generation plants.

Main subjects dealt with:

- Determination of resistance of the windings of a synchronous machine

- Detection of mechanical losses, iron losses, copper losses, etc…

- Determination of efficiency of a synchronous machine

- No-load characteristic or magnetization characteristic of an alternator

- Short circuit characteristic of an alternator

- Determination of synchronous impedance

- External characteristic of an alternator

- Control characteristic for different power factors

- V curves of a synchronous motor

- Using a synchronous motor as compensator for power factor correction

1.png)

.png)

.png)

.png)

.png)

.png)