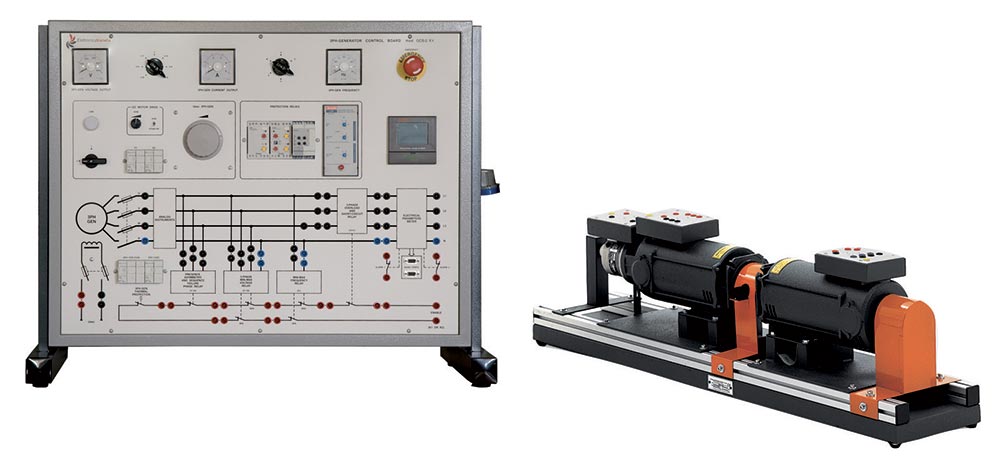

EV CONTROL AND PROTECTION MODULE Mod. GCB-2/EV

Features

This control module contains all the supply and control devices for generator set mod. MGS-1/EV and enables students to learn and experiment with electric power production and the relevant protection systems, using real industrial components. The various installed electric devices, partially connected with each other and with safety terminals, are set at work with very simple and quick operations and they enable to create, modify and check the quality of the output power. All the protection and control devices of the electric machines used in the module are exactly the same as in industrial power plants. Hence, the sequence of management operations of this laboratory power station is exactly the same as necessary in industrial power plants. As this is a training and testing system, the starting operations of the generator set and the possible parallel with the mains are intentionally left to the operator, in order to let him understand the method. This generator set consists of a common base, that is a DC motor (which simulates a turbine or an endothermic engine) and a rotary-inductor synchronous generator connected with each other. The prime mover is provided with a tachometer to control and stabilize the speed of rotation.

SKU: Machines

Category: Electrical Training Equipment, Power Generation, Distribution & Consumption

- 1 differential automatic magneto-thermal switch ln =10 A ldn= 30 mA, A-type, with minimum-voltage releasing device and emergency pushbutton with mechanical holding

- 1 electronic drive for direct current motor with armature of 160 Vdc max. 2kW, with separate excitation of 160 Vdc with feedback by a tachogenerator of 0.06 V/rev, or armature reaction.

- 1 voltage regulator 0-220 Vdc 2A for excitation of synchronous machine.

- 1 synoptic panel available on one side of the module to connect the motor-generator set with power up to 3 kVA.

- 1 wide range ammeter of 5 Aac, with switch for direct measurement of the current output or absorbed by the synchronous machine.

- 1 wide range voltmeter of 500 Vac, with switch for direct measurement of phase to phase, phase to neutral voltages output by the synchronous machine.

- 1 wide range frequency-meter 35-70 Hz.

- 5 breakable fuses for the protection of the synchronous machine.

- 1 relay of phase sequence and voltage asymmetry, for 400-V networks, asymmetry regulation range: 5-15 %; self-powered with 400 Vac

- 1 three-phase maximum-minimum voltage relay / N, control range ±10 %/ - 15 %, Ue 380-400-415 Vac, self-powered.

- 1 three-phase maximum-current and short-circuit relay; regulation range 1-5 A/5-25 Aac, auxiliary power supply: 230V 50-60 Hz.

- 1 digital analyzer of electric power suit to balanced or unbalanced systems with neutral, for measurements of voltage, current, active, reactive and apparent powers, maximum active, reactive and apparent power peaks, counting of active and reactive energy, co-generation meters, two programmable relays with function of minimum and maximum alarm programmable between measured parameters, provided with RS485/232 interface for acquisitions on a personal computer.

- Power supply: 230 Vac 50 Hz single-phase - 3 kVA (Other voltage and frequency on request)

- Dimensions: 840 x 450 x 680 mm

- Net weight: 49 kg

TRAINING PROGRAM:

Training refers to the study of machines for power generation and to control and regulation devices. The range of application of these devices is related to both big high-voltage power plants and small autonomous and/or low-voltage co-generation plants.

Main subjects dealt with:

• Determination of resistance of the windings of a synchronous machine

• Detection of mechanical losses, iron losses, copper losses, etc…

• Determination of effi ciency of a synchronous machine

• No-load characteristic or magnetization characteristic of an alternator

• Short circuit characteristic of an alternator

• Determination of synchronous impedance

• External characteristic of an alternator

• Control characteristic for different power factors

• V curves of a synchronous motor

• Using a synchronous motor as compensator for power factor correction

1.png)

.png)

.png)

.png)

.png)

.png)